Aerodynamics Laboratory

Aerodynamics Laboratory is an integral part of the Department of Aeronautics and the Croatian Aviation Teaching Centre (HZNS). The laboratory’s main function is to facilitate educational and research work of students and teachers of the Faculty of Transport and Traffic Sciences. The Laboratory enables research in experimental aerodynamics and contains a closed wind tunnel.

The Laboratory focuses on exploring the fundamental laws of subsonic (incompressible) fluid flows. Undergraduate Aeronautics students use the closed wind tunnel to conduct laboratory exercises for their term papers. Students learn about the wind tunnel, the instrumentation (instruments that measure pressure, differential pressure, velocity, and force), and the way to determine the distribution of pressure and resultant force on the aerofoil.

Three basic laboratory exercises are carried out: aerofoil aerodynamics and pressure distribution, aerofoil aerodynamics and aerodynamic force and moment, and boundary layer measurements on a flat plate.

The objectives of the laboratory exercises include:

- demonstrating physical phenomena and concepts taught in lectures

- developing positive attitude towards experimental work

- training in observation, deduction based on observation, critical awareness, keeping laboratory notes, writing reports, designing an experiment, and collecting specific data

- encouraging independent thinking, positive attitude towards research and development, sense of affiliation with the faculty, and cooperation in small groups to solve experimental problems.

The Research Enterprise

Low-speed wind tunnel

Low speed wind tunnel is shared educational equipment of the Faculty of Transport and Traffic Sciences and Department of Aeronautical Engineering, FMENA. It is located at the University Campus Borongaj. The wind tunnel at the Aerodynamics Laboratory is a closed tunnel made of plywood with a double wall and ribs in between. The main parts of the tunnel are test-section, contraction section, flow straighteners, diffuser, fan, drive motor, and turning vanes. The tunnel has a circular cross-section, except for the test-section, nozzle output and entrance to the first diffuser that are elliptical. Test-section is open on the sides. Dimensions of the test-section are 0,352 x 0,310 m, 0,450 m in length. The total power required for the operation of the tunnel, or increase pressure expressed as the effectiveness of the tunnel, ER, and depends on airspeed. The drive section (asynchronous motor and fan) is located in a metal casing mounted on a separate carrier. The engine controls the frequency which is the independent variable that determines all the other variables. Maxim motor frequency is 50 Hz, power 4 kW, and speed 2900 RPM.

FriMultilevel piezometer

Multilevel piezometer is used for relative pressure measurements. It has a fluid reservoir and 30 transparent tubes which are connected to the pressure measurement points. One tube measures the reference pressure, and the remaining 29 measure local pressures. Each tube is fitted with a scale to read the level of the liquid. The difference between the local and the reference pressure (reflected in the different fluid levels) indicates the relative (differential) pressure. Multilevel piezometer can be tilted to increases the reading resolution.

CNACA 2421 airfoil model with pressure taps (metalic, c=0.15 m)

Airfoil model has an opening at the front edge and 14 pressure taps on the upper and lower surfaces. Pneumatic tubes connect the pressure taps to the multilevel piezometer. NACA 2421 airfoil model cord length: c = 0.15 m

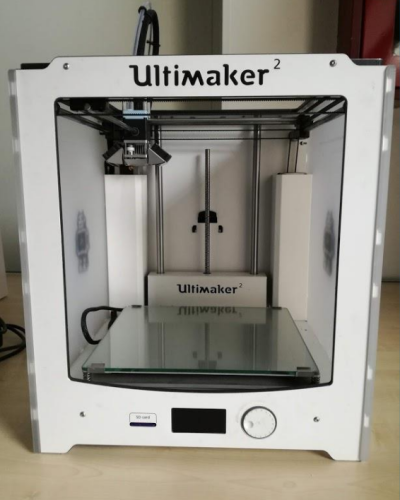

3D printer Ultimaker 2

A material design printer that designs and builds 3D models and products using an additive manufacturing process from CAD software-created 3D design models. Features: loudness while working: 49 dB, material: PLA or ABS, layer resolution: do 20 μm, travel speed: 30 do 300 mm/s, build volume: 230 x 225 x 205 mm ,recommended filament diameter: 2.85 mm, usage cost: ~ €0.05 / cm3 (material and power) ,software: Cura (free, open access).giat at pro, mea aperiam.

Air velocity meter kit

Measuring air velocity in the test section of the low-speed tunnel. Air velocity meter kit contains:

- 1 handheld digital manometer Series 475 MK III with a range of 0-9 mbar at 0.5% accuracy and 1Hz sampling

- 1 Pitot-static tube 166-6-CF, diameter 1/8” (3.2 mm) and length 6” (15.24 cm)

- 2 tubes with static openings

- 2 rubber tubes length 9 ft and 3/16” (4.7625 mm) diameter

- 9 V battery, hole puncher, conversion table.

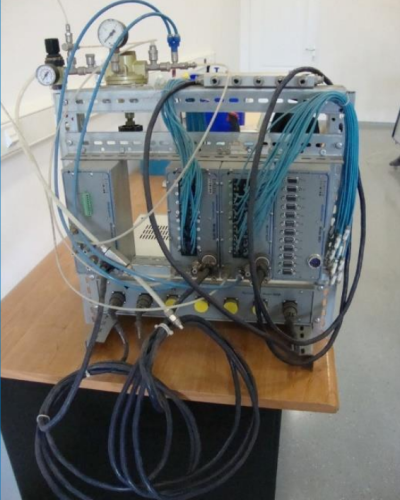

NetScanner 9000 pressure measuring system

Pressure and differential pressure measuring system composed of several 9000 series modules.

- two 9016 Intelligent Pressure Scanner modules taking measurements and collecting data on gas pressure

- two 9034 modules

- one 9021 module

- NUSS software for PC

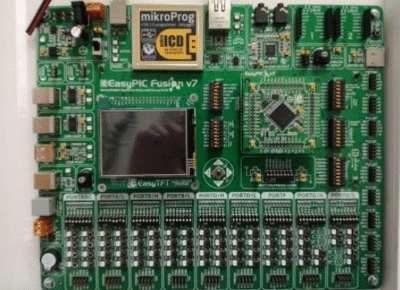

EasyPIC Fusion v7 development board

Development Boards EasyPIC FUSION v7 and matching MCU card. Features: power supply: 7 to 23VAC or 9 to 32VDC or via USB cable (5VDC), board dimensions: 266 x 220mm (10.47 x 8.66in) ,power consumption: ~143mA (all modules disconnected).

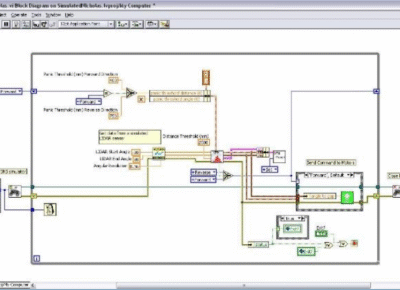

LabVIEW system-design platform and development environment for visual programming

LabVIEW (short for Laboratory Virtual Instrument Engineering Workbench) is a graphical language for measurement, automation, and visualization of processes. It is used for developing measurement and test apps, data acquisition, and instrument and process control and analysis. At the Aerodynamics Laboratory, Labview is used to collect pressure measurements on the airfoil model in the test section of the low-speed tunnel. Pressure data from all measurement points and other relevant data (airspeed, angle of attack, etc.) were used to develop a Labview application that calculates the lift on the airfoil model.